Robotic Welding Fixtures Manufacturer

We are Manufacturer, Supplier (and Fixtures Services Provider, Fixtures Solutions Provider) of Robotic Welding Fixtures, Robotic Cell And Fixtures, Welding SPM Machine Fixtures (Special Purpose Welding Machine Fixtures), Air vent Assembly Fixtures, Jigs Fixtures, PU (Polyurethane) Assembly Fixtures, SS (Stainless Steel) Pipe Workstation, Holding Fixture Resting, Ultrasonic Welding Fixtures, Rotary Fixtures (Rotary Welding Fixtures). Our setup is situated at Pune, Maharashtra, India. Majorly we target customers from ALL OVER MAHARASHTRA.

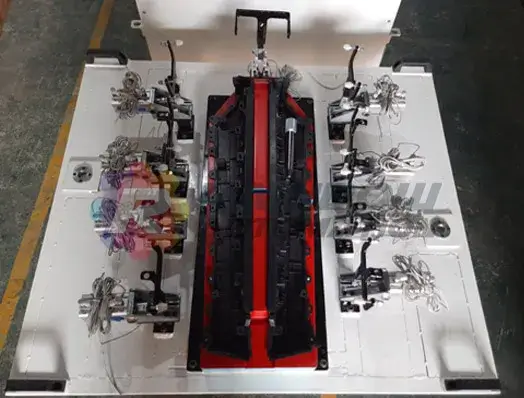

Robotic welding fixtures are specialized tools that securely hold and position workpieces during the welding process, ensuring precision and consistency in the welds. They often incorporate clamps, supports, and adjustable components to accommodate various shapes and sizes of materials.

Robotic Welding Fixtures are precision-engineered tools used in conjunction with robotic welding systems to ensure the accurate positioning and secure holding of workpieces during automated welding processes. These fixtures help enhance the productivity and quality of the welding process by ensuring that the robot follows the exact welding path, minimizing errors and reducing the need for rework. Designed with robust materials like SS (Stainless Steel) and MS (Mild Steel), these fixtures can withstand the demanding conditions of industrial environments. Robotic Welding Fixtures are highly optimizable to suit specific applications, making them an integral part of modern manufacturing setups focused on automation.

Salient Features:

- Designed for high-precision robotic welding applications

- Made from durable SS (Stainless Steel) and MS (Mild Steel)

- Customizable for specific welding tasks and workpiece sizes

- Enhanced welding accuracy and consistency

- Improves production efficiency and reduces manual labour

Applications:

- Automotive manufacturing

- Heavy equipment fabrication

- Aerospace component welding

- Industrial machinery production